Plant Maintenance

Systems Supporting Maintenance and Access to Knowledge

The AMAGE system supports production plants with particular emphasis on plants with continuous production. Several solutions focus on direct operational support for the line employees (closest to events), and effective coordination of all work. Unique solutions in the area of control works and rounds allow the integration of rounds data and the results of the annual review in one central system. Our solutions help conduct annual reviews using external teams, providing key information for the operation of the plant in a coordinated and continuous manner.

DEMO Version, Implementation, Purchase

Data Acquisition & Visualization

Plant Structure

Most industrial plants have countless data sources about their devices, machines, and constructions. Frequently they are either ERP systems or many separate Microsoft Excel documents. Access to this data is often straitened. Our solution allows you to integrate various sources into one coherent platform, to which people responsible for coordinating certain areas and employees have access. Moreover, this data can be expanded - through internal operations and during purchasing new equipment/installations - by the information provided by the suppliers.

Access to documentation

Documentation in the production plant is usually stored/shared either by ordinary paper documents or by a distributed data set in electronic form (files, CDs, scans). Often access to this information during ongoing critical repair works is limited. The AMAGE system facilitates access to this data and its cataloging/searching. Importantly, we provide this information also in places where access to the ICT network is difficult or environmental conditions are extreme.

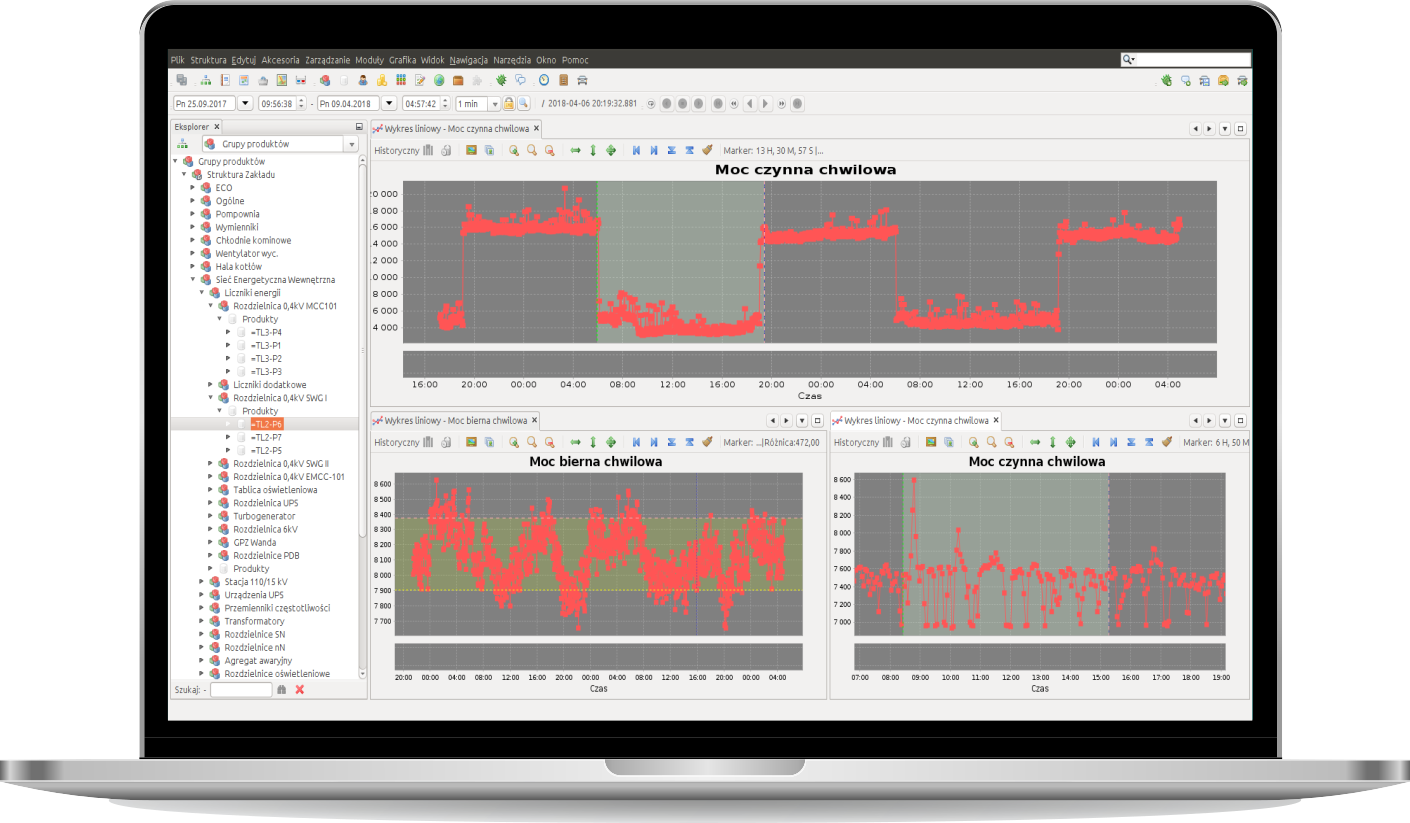

Measurement monitoring

In addition to supporting users in carrying out manual work and integrating this data on a common platform, the AMAGE system also allows the integration of automatic data - whether from external DCS systems or using their own data aggregators directly from the devices. That allows expansion of the analytical data and improvement of making decisions by work coordinators.

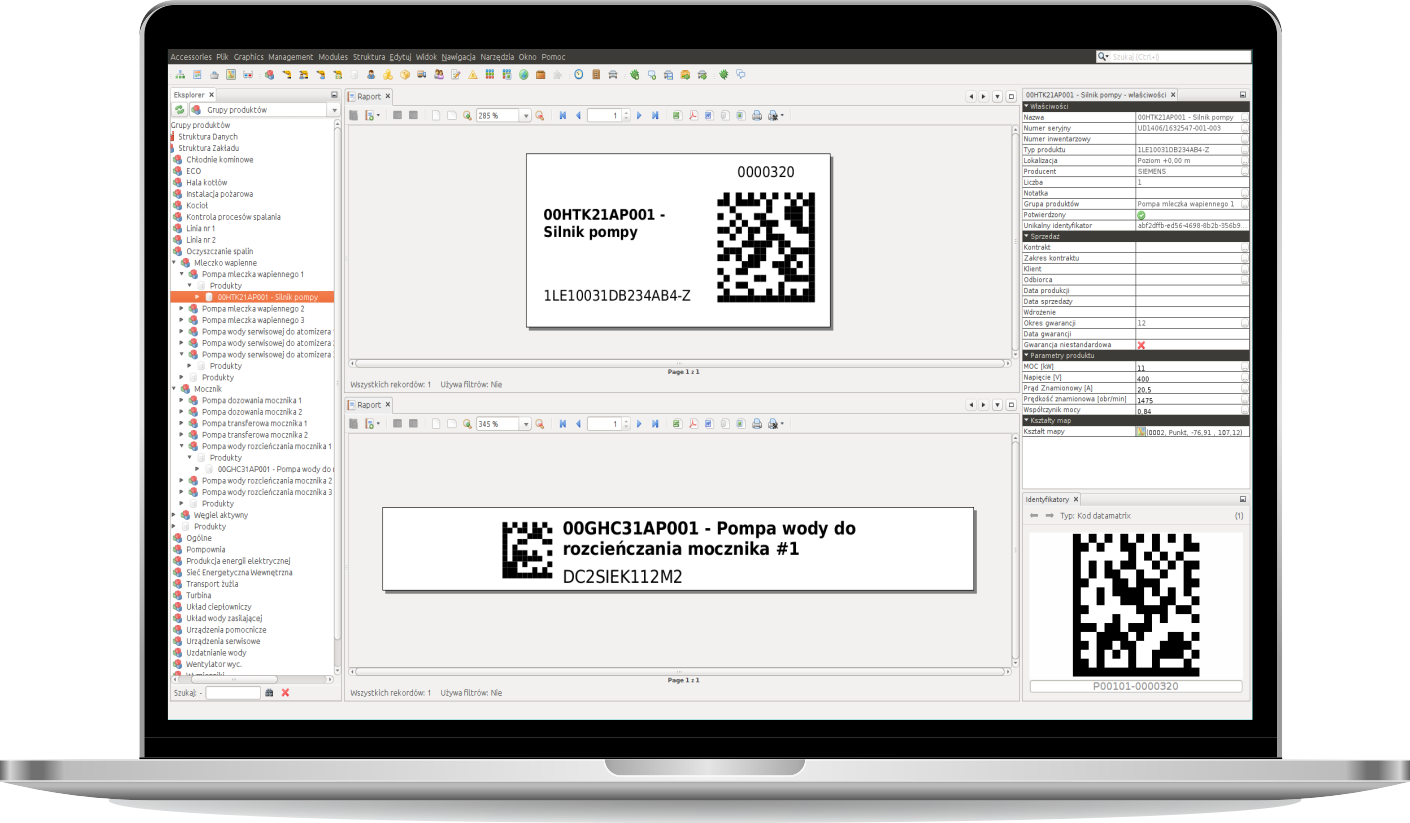

Markings

A key aspect of maintenance work is the speed of access to information. While creating the structure of a production plant, the AMAGE system allows the simultaneous generation of unique identifiers in the form of 2D codes or RFID tags, even in the most complex areas. Modules support on-site inventory works by using mobile devices and working in offline mode. That simplifies and accelerates all work, which allows you to build an efficient knowledge base, and speed up other works carried out by the AMAGE system.

Maintenance

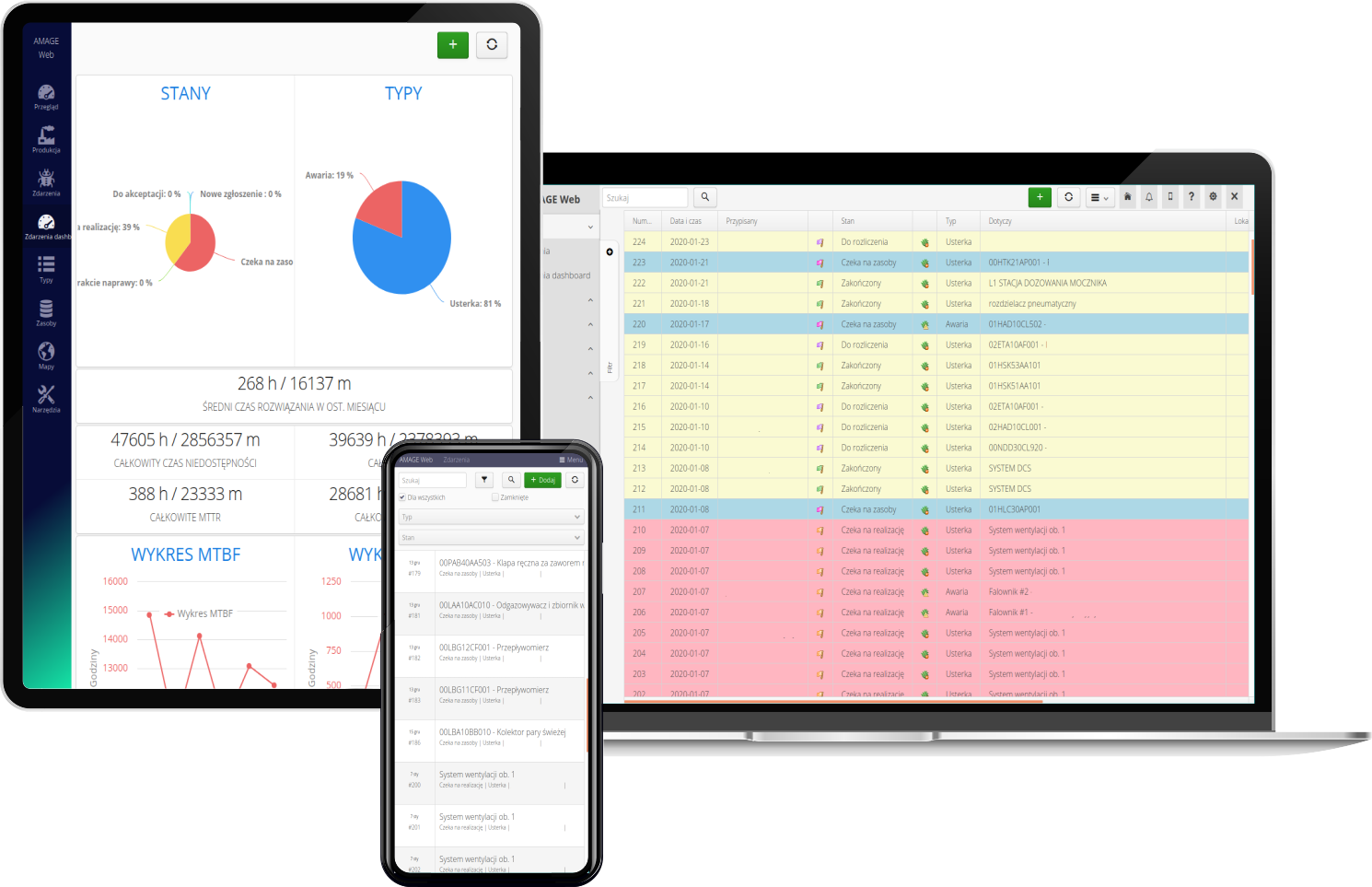

Service Events

The efficient operation of Maintenance teams requires a management system of service requests. Being user-friendly - limiting the time spent in the application and focusing on the actual repair work carried out - is the key. Our solution facilitates all of those works, and additionally, by integrating with our own warehouse solution or external systems, it simplifies the financial settlement of service requests. Moreover, further analyses of reliability, performance, and notification mechanisms allow for fast and efficient operation of the Maintenance department.

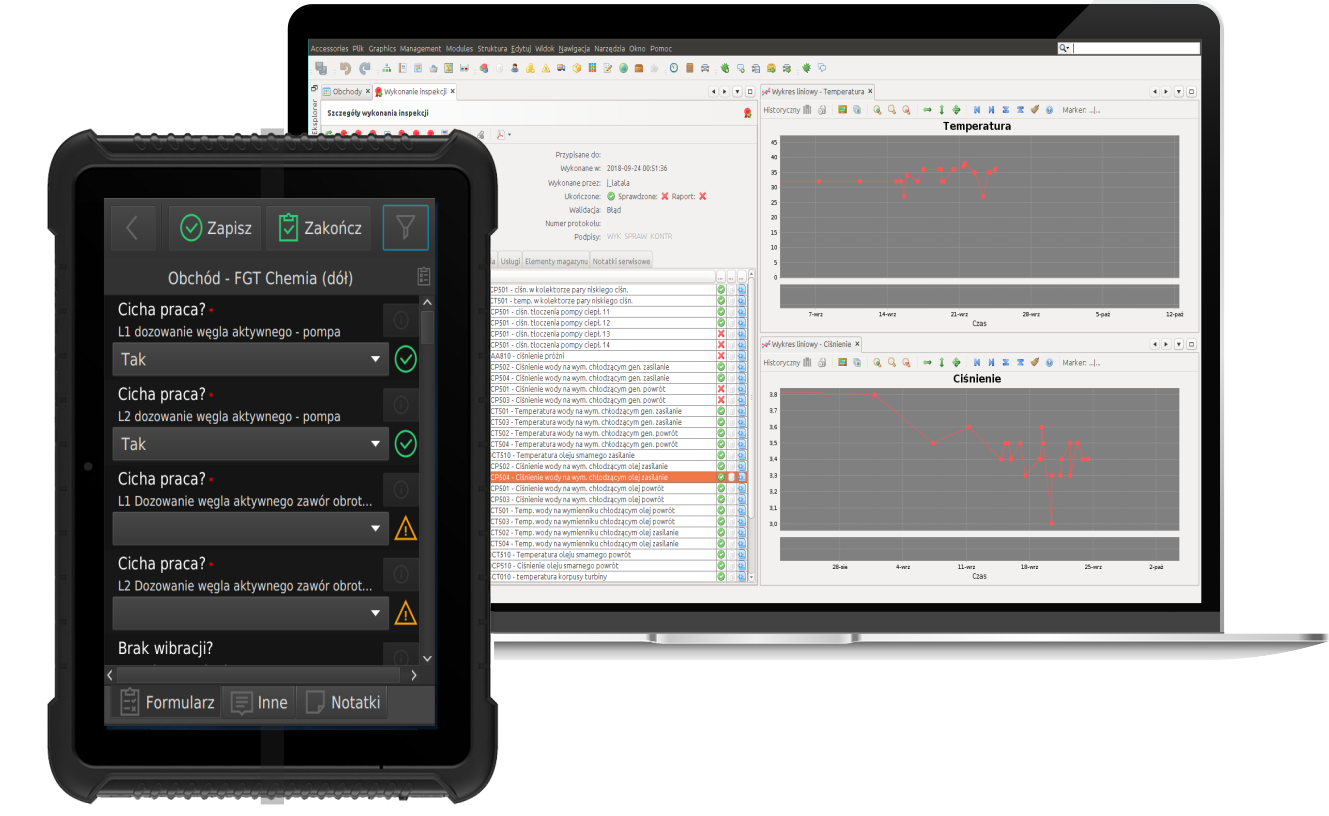

Inspection Rounds

In industrial plants with continuous maintenance, especially crucial are areas that require constant supervision. Not all of the operations can be automatized, and not all measurements can be made by DCS systems. The information collected by employees during periodic inspections is also essential. The AMAGE system facilitates this work and provides employees with a simple interface for entering the data observed during the inspection rounds. At the same time, it integrates all of this data to give the possibility of analyzing measurements and detecting anomalies not only by automatic systems. Coordinating managers can coordinate the rounds of work along with full analytics and reminders about the performed work.

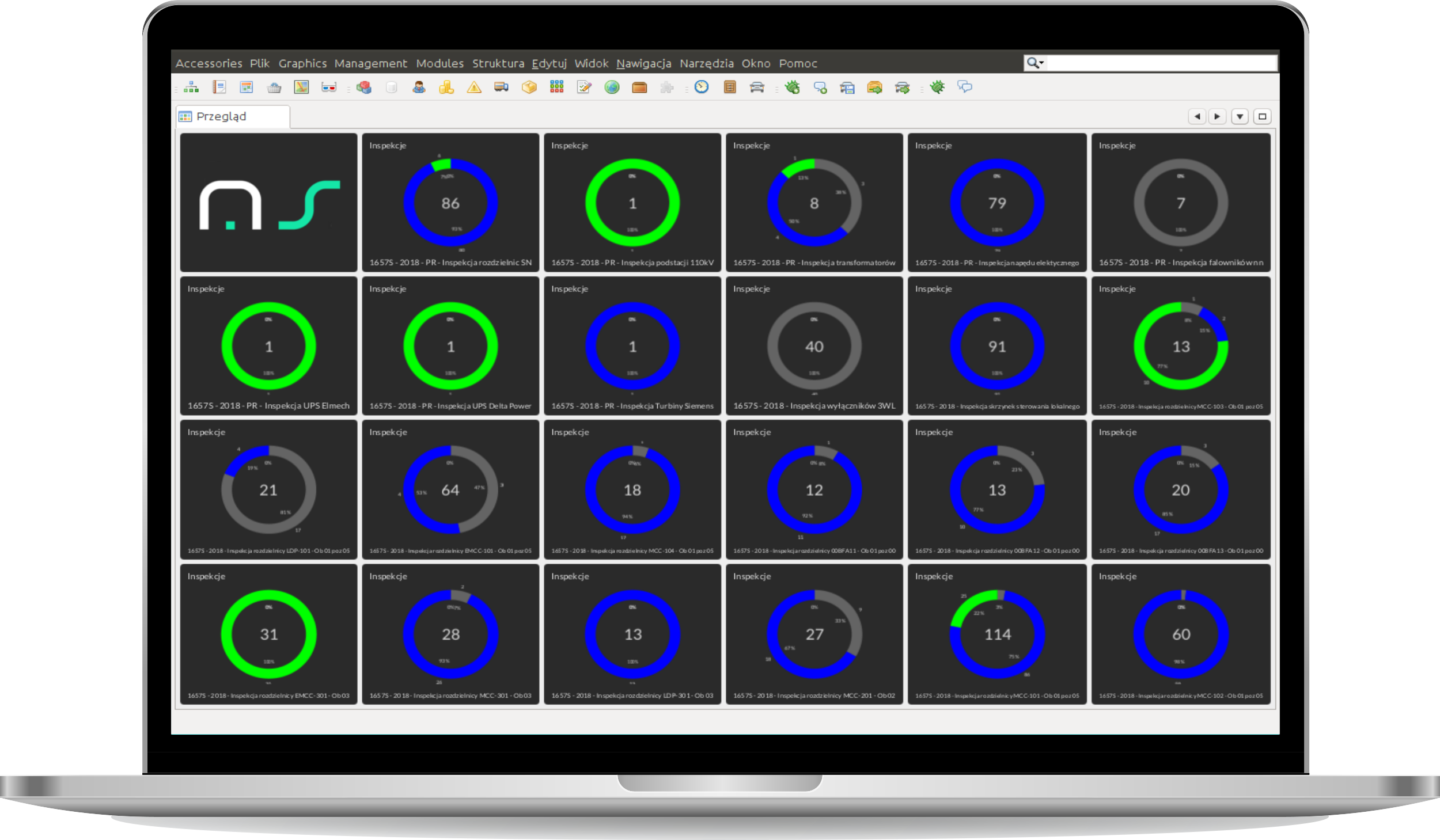

Control Cards/Inspections

Production plants and equipment/machines located there require continuous technical reviews. Often, these procedures are subject to legal, normative, or manufacturers' requirements. At the same time, operations such as annual reviews pose a demanding task to coordinators to manage their work, subcontractors, and the completeness of work. The AMAGE system has unique and proven solutions to facilitate this work. It allows users to define necessary work templates, set deadlines and schedules, and monitor ongoing work, including acceptance procedures and electronic signatures. The AMAGE system simplifies and speeds up the performance of annual reviews, and at the same time integrates all data on one platform, providing unique knowledge immediately after each audit work.

Safety & Integrity

LOTO Procedures

LOTO (LockOut/TagOut) procedures allow for the supervision of the shutdown of hazardous equipment. By means of procedures for switching on/off devices defined in the system, we can track and supervise the process in accordance with the organization's requirements. Full procedure involving persons authorizing and performing work. Team Lock Boxes. Support in documentation and information about performed operations.

Permissions for Work

The work permit module allows you to organize, monitor and supervise the process of hazardous work. With the help of defined templates and rules, the persons authorizing work can perform and order all the necessary security activities. The execution order along with full tracking of acceptance, release to work and release of equipment are recorded digitally. The current register of works allows for responsible decisions of the team controlling the works.

Common modules